Crafting Precision and Innovation in Die Casting Mold Solutions

Crafting Precision and Innovation in Die Casting Mold Solutions

Blog Article

In the intricate world of precision manufacturing, die casting mold making is a vital technique that breathes life into high-quality metal parts. Junying, a prominent die casting mold manufacturer in China, has carved out a niche by delivering bespoke die casting mold solutions that cater to the multifaceted demands of industries like lighting, medical, automotive, and electrical. In fact, just last year, we collaborated with a leading automotive company to create lightweight yet robust engine components, showcasing our ability to innovate and meet the most stringent requirements.

At Junying, we see die casting as both a science and an art. It demands precision, advanced technology, and a relentless pursuit of quality. Our process involves a specialized die casting mold forging machine, where liquid metal is injected into the mold cavity under high pressure. This technique not only ensures that the final product boasts superior mechanical properties but also eliminates common defects like porosity and shrinkage. It's like turning molten metal into a masterpiece, one mold at a time.

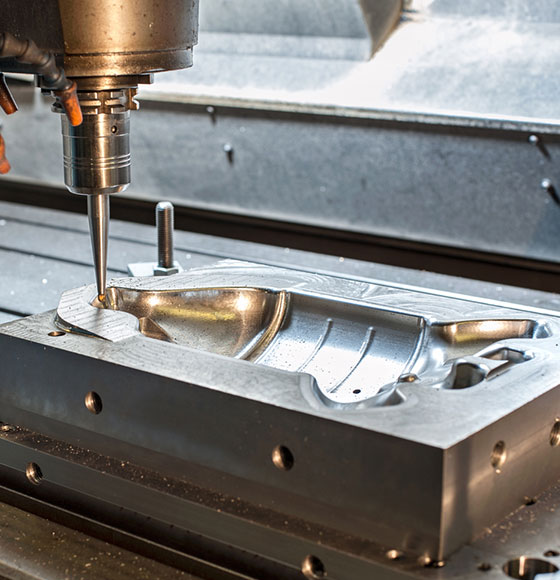

Our expertise is evident in every mold we create. The fixed and movable mold halves are precision-machined to exact specifications, using high-quality materials like aluminum, zinc alloys, and various grades of steel. These materials are chosen not just for their durability but also for their ability to produce parts with exceptional surface finish and dimensional accuracy. It's like building a solid foundation for every project we undertake.

Our manufacturing facilities are equipped with the latest technology, including CNC machining centers, lathes, milling machines, spark erosion machines, and a comprehensive polishing system. This advanced infrastructure, combined with our team of highly skilled engineers and technicians, allows us to produce custom die casting molds according to customers' specifications, drawings, or even samples. Recently, we used this setup to create a unique lighting fixture mold for a designer who wanted to incorporate intricate patterns—a challenge we gladly accepted and successfully completed.

But our journey doesn't stop at mold making. We also specialize in die casting lock parts, offering a wide range of options, from door locks to car locks. These lock parts are manufactured using the same precision and quality standards that we apply to all our products. In fact, we recently developed a new type of smart lock mechanism that combines traditional die casting with modern IoT technology, a testament to our ability to stay ahead of the curve.

With over a decade of experience, Junying is more than just a manufacturer—we're a trusted partner. Our robust quality management system ensures that every step of the production process is meticulously monitored and controlled. This dedication has earned us recognition from over 100 customers worldwide, including some of the biggest names in the industry. One of our proudest moments was receiving an award for "Best Die Casting Innovation" at a recent industry conference, a nod to our relentless pursuit of excellence.

If you're looking to bring your die casting project to life, we'd love to hear from you. Visit our website or contact our expert team today to learn more about our services and how we can help turn your ideas into reality.